All LED drivers need various protections to prevent failures to protect the system where power suppliers are utilized. There are many types of protections related to voltage, thermal and current which improves the reliability and functionality of LED drivers.

However, these protections have a list of specifications. This blog post will explain what they mean and how they help your LED drivers.

LED Driver Thermal Protection

Power supplies use over-temperature protection (OTP) to disconnect or lower the power from an electronic circuit if the internal temperature exceeds a safe value. The shutdown process starts after the circuit triggers a signal that indicates high temperatures.

Thermal protection is crucial to prevent heat damage to the equipment components. The reason why temperature rise is different and usually happens for both environmental factors and the components themselves depends on the power capacity, design, and quality. There are two types of thermal protection for a reliable luminaire design:

a. LED Driver internal over-temperature protection by a thermal switch

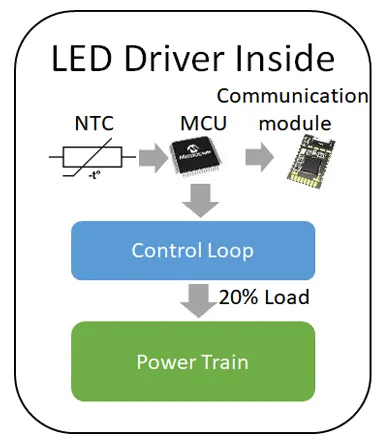

The internal OTP circuitry usually includes an NTC thermistor or a thermal switch connected with an MCU or an analog circuitry that detects the thermistor or thermal switch signal to trigger the protection. Usually, the thermistor or thermal switch is put right beside the hottest or most thermal sensitive components, or we say the weakest link to the temperature to react quickly once over-temperature happens. You can find this type of system in other appliances such as clothes dryers, microwaves, and refrigerators.

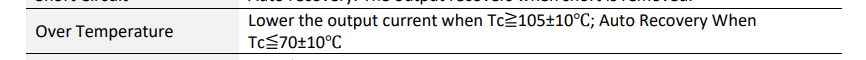

For LED drivers, OTP usually does not switch off the light but turns the light output down to cool down the LED driver as below shows from the datasheet.

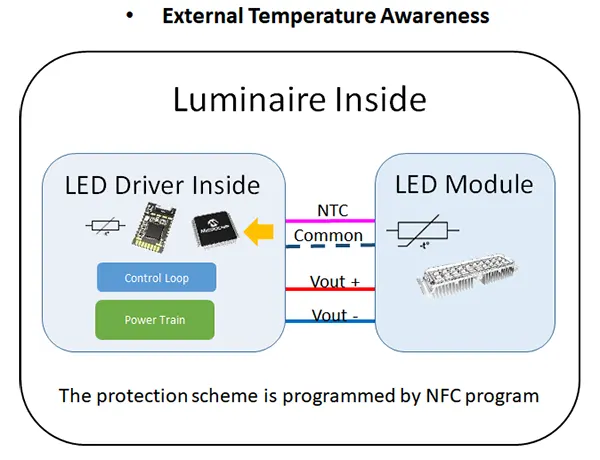

b. LED Driver external over-temperature protection by NTC resistor on LED board.

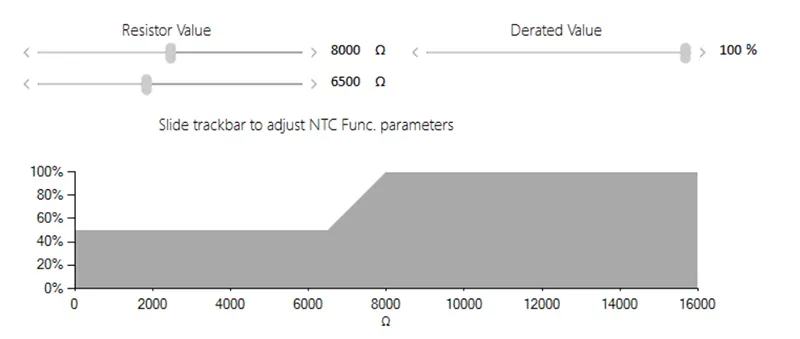

The NTC thermistors are put on a LED board to monitor the temperature of the hottest point of the board. And the LED driver has two wires connected to those NTC thus the thermal signal can be transferred into the MCU inside the LED driver. Once the LED drivers know the LED board is too hot, they lower the output current, thus protecting the LED from overheating.

And the parameter of NTC can be by uPowerTek programming software, as the interface below shows.

LED Driver Over Current Protection

It’s a protection against current beyond an indicated current rating in equipment. Nowadays, OCP circuitry is efficient enough to operate instantly, avoiding other types of overcurrent such as short circuits. For most cases, OCP is talking about output current rather than input current, and OCP is crucial for constant voltage output LED drivers.

Usually, an LED driver is not suggested to latch or hiccup if the load on a single line exceeds a safe value and users are more comfortable with a lower current protection mode. The figure below shows a typical description of OCP for an LED driver.

LED Driver Short Circuit Protection

Most electronic accidents occur from a short circuit. Luckily, developers have designed sophisticated short circuit protection (SCP) that protect all appliances, including LED drivers. SCP is the first barrier against excessive currents, making the SCP trip the device and break the circuit.

Short circuits occur when a low-resistance object gets a high-volume electrical current. In other words, you’ll get a short circuit if a conductive path or object touches a hot wire when they aren’t supposed to.

Short circuits can damage the key components such as MOSFETs, diodes and electrolytic capacitors, causing a significant failure in a LED driver.

Short circuits can lead to electrical shock, equipment damage, and even fire, so taking preventive measures is the key to avoiding these situations.

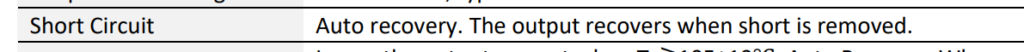

Fortunately, we have many options before this happens, such as using power supplies with reliable SCP functions. Here is an example describing the output OVP from uPowerTek LED driver datasheets. SCP mode has to be auto-recovery for LED drivers rather than latch off.

LED Driver Over Voltage Protection

Another essential LED driver protection feature is the overvoltage protection which shuts down the supply when it detects an irregular voltage that exceeds a safe level.

As well as the other types of protections, OVP protects a circuit and its electronic components from permanent damage.

There are many reasons why an over-voltage occurs, but overall failure in the distribution lines or within the supply itself is the primary cause. If you’ve dealt with over-voltage in the past, you can consider its duration and magnitude to choose effective protection. It usually includes having a threshold voltage attached to where the control circuit shuts down the LED driver. Some factors you should take into consideration when choosing OVP:

a. Input OVP

Input overvoltage occurs for different reasons, and the main ones are the following.

- Wrong connection of input cable. If the technician connects the 220Vac line to line rather than line to neutral, then the real input voltage can be 380Vac thus it will damage the LED driver.

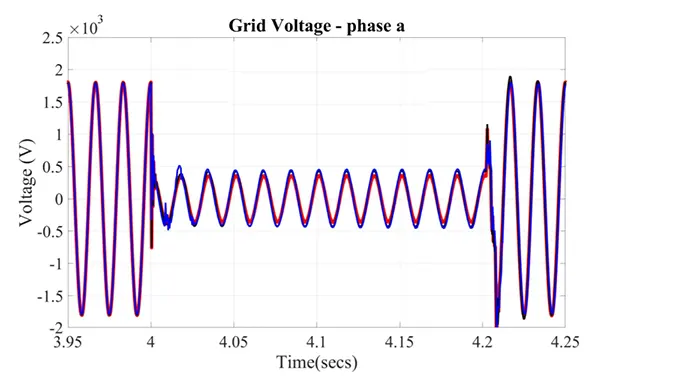

- Unstable grid voltage. This usually happens in developing countries where the electricity is not stable. The fluctuation at +/-50% of normal operation voltage is often seen in those areas.

To prevent LED drivers from being damaged by those reasons, the designers usually do two designs in the LED drivers.

- Design a high margin for the input voltage range. For example, uPowerTek designers make sure that the 220Vac rated LED driver is able to work continuously for at least 2 hours with high voltage of 380Vac input thus even if the input cable is not connected well, the LED driver can be still alive.

- Design input OVP latch off circuitry. With this design, the 220Vac rated LED driver input voltage can withstand more than 400Vac in the off state.

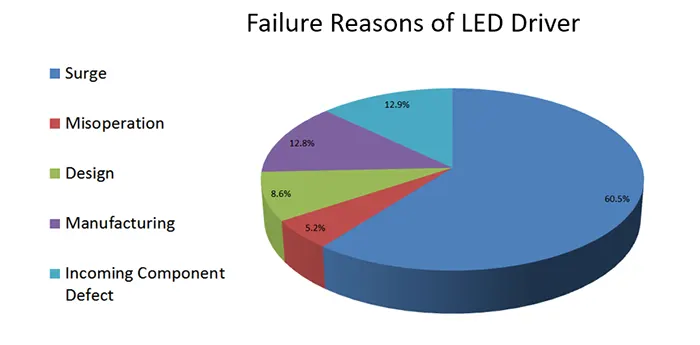

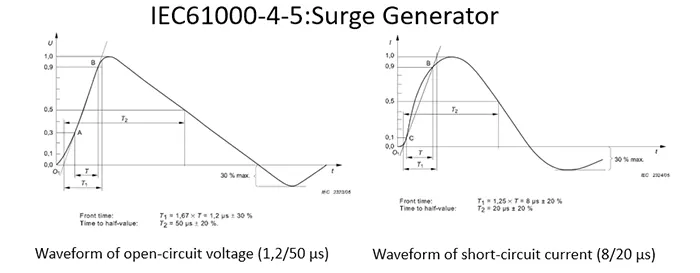

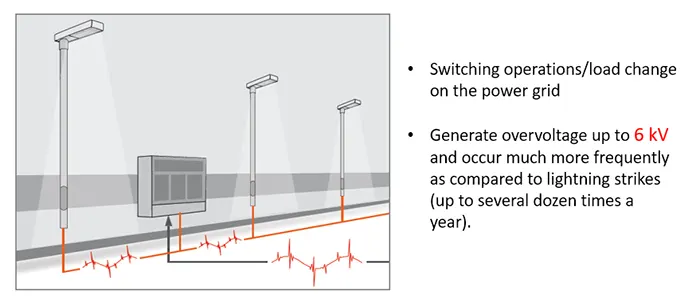

b. Input Surge (Lightning) Protection

Surge protection is the component that deals with high voltage peaks resulting from lightning strikes. It can be categorized by two reasons:

- Lightning. This is the main reason that street light fails in tropical areas and a great threat to the outdoor luminaires.

Fortunately, we have good ways to reduce lightning damage to a very low level as long as the proper lightning protection design is done with high quality and protection level LED drivers. The mainstream protection level of LED drivers is very high, up to 10kV according to IEC-61000-4-5 for common mode since most of the lightning surges are common mode.

- Surges due to the inductance in the cable and on/off of high power devices in the same grid network. This is often affecting the differential mode voltage between line and neutral, and the most popular protection level is 6kV also according to IEC61000-4-5.

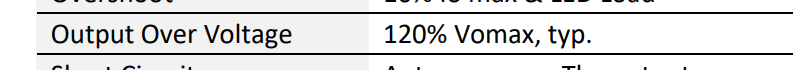

c. Output OVP

An effective output OVP should detect any potential overvoltage suspending the output. Like OCP in constant voltage LED drivers, OVP is vital for describing constant current LED drivers. It usually activates when the voltage exceeds 115% to 130%. Here is an example illustrating the output OVP from uPowerTek LED driver datasheets.

Summary

If you’re looking to improve the reliability and quality of luminaires, setting efficient protections will keep everything safe. High-level LED driver protections are crucial for fixture manufacturers to meet safety requirements and prove higher quality standards. So protection is a key factor for luminaire designers and buyers to discriminate high quality LED drivers from average.