LED lighting industry has been evolving for almost 20 years, and the power of the lights is becoming higher especially in the grow light, stadium light and other high power light applications since the users are trying to reduce the light quantity to cover the same area so as to save the installation and maintenance cost. And the luminaire designers are often suffering from the hot LED driver especially when fixed inside a light fixture, which leads to higher failure rate and shorter life time. So this article tells some key steps to make sure the LED drivers are properly used in a fixture.

1. The key parameter for driver temperature: Tc (case temperature).

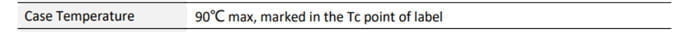

Tc is usually seen in 2 sections of a LED driver datasheet as below. The first point is in the technical data section where the maximum allowed Tc is shown and a typical value is 90 which can also been found from safety certification reports.

And the second area is the lifetime vs. tc curve where the lifetime can be found according to the real measured case temperature. Apparently that lower temperature results in higher lifetime which is essential for high power luminaire designs.

So to improve the thermal design for the LED driver, we have to understand what kind of factors impact the Tc and generally speaking, designers have to reduce the heat generation and improve the ways of heat dissipation.

2. Find high efficiency LED drivers.

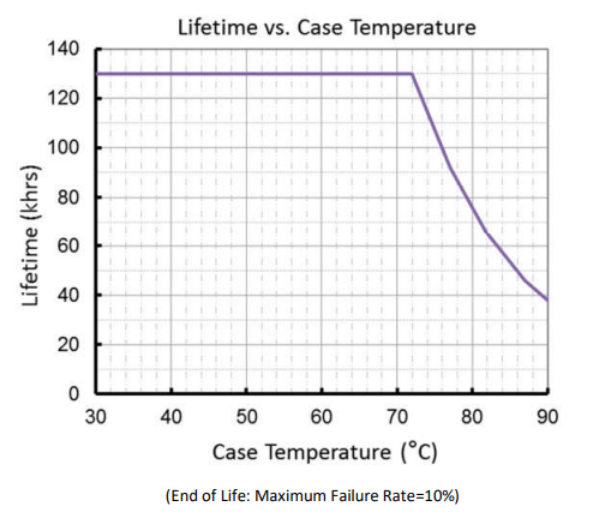

With the same power rating, higher efficiency means less power loss or heat generation. The following table shows typical high performance driver efficiency.

| Power | 100W | 200W | 300W | 400W | 500W | 600W | 700W | 800W | 1000W |

| Isolated driver Efficiency | 90% | 92% | 93.5% | 94% | 94.5% | 95% | 95.5% | 96% | 96% |

| Non-isolated driver Efficiency | 94% | 94.5% | 95% | 95.5% | 96% | 96.5% | 97% | 97.5% | 97.5% |

Users need to find the right input voltage range which impacts the efficiency greatly as the figure below shows. And the load condition also plays a role to the value as shown, the 90~100% load condition is friendliest to high efficiency operation.

Nowadays more and more designers are beginning to use non-isolated drivers for high power application not only because of the cost, but also higher efficiency.

3. Heat dissipation.

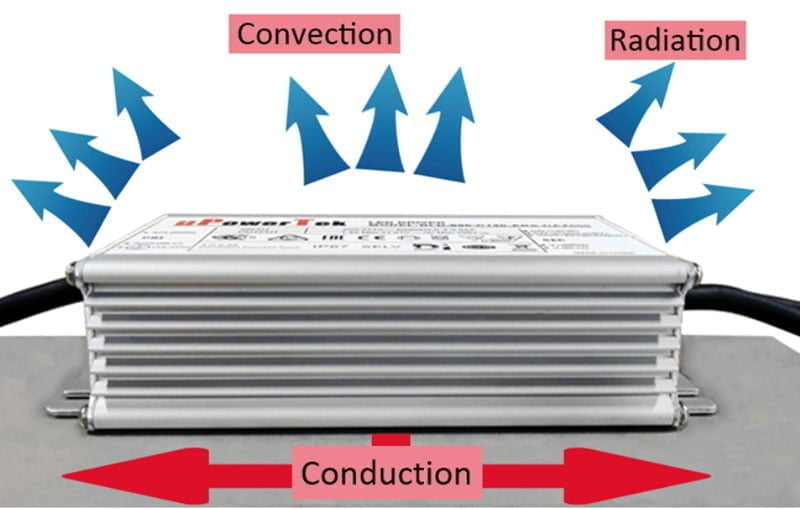

There are 3 ways for heat to dissipate: conduction, convection and radiation. Generally speaking, conduction refers to the transmission of heat by direct contact, convection is the movement of heat by motion of substances like air or water while radiation is the transfer of energy by electromagnetic waves.

Conduction is able to handle the majority of the heat if the contact of the driver and light fixture is close enough and better if there is silicon glue between they to increase the contact area and heat transfer. And conduction is the most important way for cooling down the driver when the driver is fixed inside the case where convection or radiation almost do nothing for thermal performance since there is no air flow inside a housing and electromagnetic waves also can not be radiated outside in a metal housing. So for high power luminaire, making sure the LED driver case is fully attached to the luminaire housing is extremely important.

And if the driver is fixed externally, convection and radiation could play big role for cooling down the driver and normally the thermal situation is quite good in this application.

4. Special ambient.

The ambient temperature can be up to 85degC in steel plants where normal LED driver can possibly trigger over temperature protection or even break down directly. By using unique technology and high quality components inside the driver, uPowerTek is offering the choices for those kind of special usage.

Summary

The LED driver thermal performance is one of the key considerations of a reliable and high quality luminaire design and understanding the ways for cooling down LED driver helps the designers to make better lights.