Horticulture lighting is not new lighting application since the era of HID, but the usage and evolution of LED lighting have fundamentally updated the industry by being able to customize the PAR for different plants, and it thus becomes one of the fastest growing markets globally especially in US and Europe. This article provides the ideas of how to improve the lighting efficacy for grow lights and make a better fixture.

The impact of light to growing

In the natural spectrum, the effects of different bands on plant physiology are as follows:

- The effects of 280~315 nm on morphological and physiological processes are minimal;

- The chlorophyll absorption of 315~400 nm is less, which affects photoperiod effect and prevents stem elongation;

- The absorption ratio of chlorophyll to carotenoid was the largest at 400~520 nm(blue light) and the effect on photosynthesis was the greatest;

- The absorption rate of 520~610 nm pigments is not high;

- The chlorophyll absorption rate of 610~720 nm(red light) is low, which has significant effect on photosynthesis and photoperiod effect;

- The absorption rate of 720~1000 nm is low, stimulating cell lengthening, affecting flowering and seed germination;

- >1000 nm converted to heat.

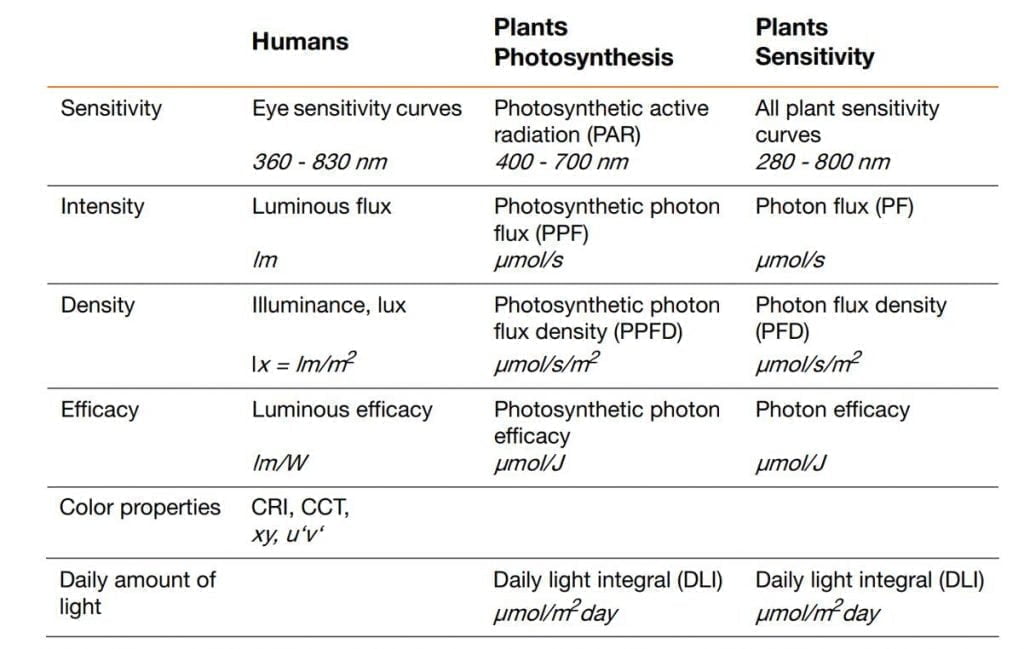

Basically, Photosynthetically active radiation (PAR) is the range of light wavelengths that enables photosynthesis in plants. The actual range is from 400 to 700 nanometers (nm).

What is Photon Efficacy?

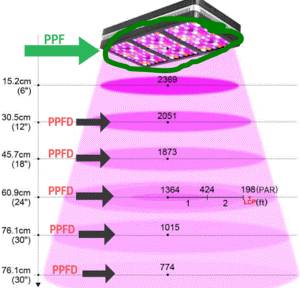

The light loses strength as it travels from source to endpoint (from grow light to plant). You’ll notice on most grow light intensity charts, the PPFD numbers decrease with increased distance from the light. That’s why paying attention to your grow light hanging height is so important when growing.

How to use energy efficiently for grow lights?

In order to invest in the proper horticulture lighting system to meet your cultivation and business goals, you need to know the PPF, PPFD, and photon efficiency to make informed purchasing decisions. However, these three metrics should not be used as sole variables to base a purchasing decisions. There are several other variables such as form factor and coefficient of utilization (CU) that need to be considered as well.

All factors need to be used in combination to select the most appropriate systems based on your cultivation and business goals, and the take home message is that PPF, PPFD, and photon efficiency are the proper metrics used by scientists and industry leading horticulture lighting companies. If a company does not provide you with the correct metrics used for horticulture lighting, they should not be selling horticulture lighting systems, and you will not be able to verify the true efficacy of their system.

Choosing right LED drivers to improve the light fixtures

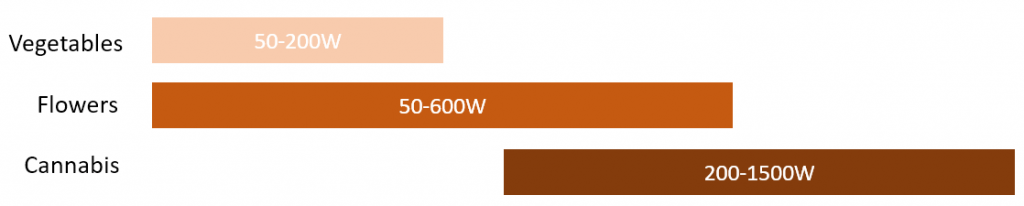

Choose the right power for the light fixtures.

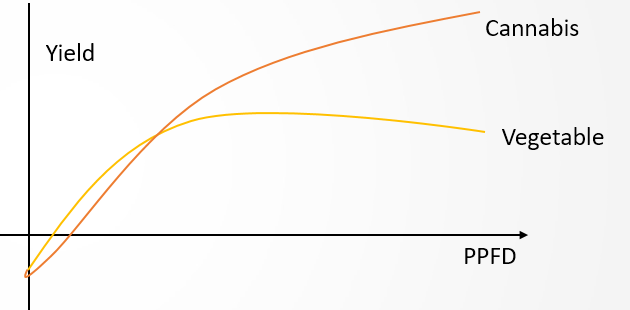

The reason is that different plants react differently to light output which is described by PPFD.

Choose the right input voltage for light fixtures.

There are mainly two different input ranges to cover most of the grow light applications. 120-277Vac and 200-480Vac. With the power range increasing and cable cost increasing, more and more users are choosing the high voltage input to decrease power loss on cable and the cable cost.

Higher efficiency drivers result in higher light efficacy and longer life.

Tier 1 LED driver manufacturers provides higher than 95% efficiency for higher power drivers like 600-800W and 94% for 300-400W. In the high power application, 1% efficiency difference means a lot especially about over 10% heat generation difference, thus leads to 10-20C internal component temperature difference. As we know that 10C lower temperature of capacitor leads to twice life time and better reliability on MTBF.

Single high power driver or multiple lower power drivers.

For high performance drivers, single high power driver should be the main stream choice. The reason is as following:

- Higher efficiency. The more low power drivers are used, the higher loss and lower efficiency the system get.

- Simplicity of internal wiring during manufacturing.

- Doubling or tripling the failure rates. More drivers means higher failure rates and more difficult to maintain.

- Inrush current. Multiple drivers leads to higher inrush current during turn on.

- Asymmetrical startup. Multiple drivers has different start up time which leads to uncomfortable startup.

- Higher dimming control driving current. Usually a single light fixture controller is able to drive at least 50pcs of drivers, so the more drivers in single fixture, the less fixtures can be driven. Also more drivers in the control loop can lead to higher voltage drop on the dimming cable, thus inconsistency of the light output can possibly be seen.

uPowerTek solution for grow light fixtures.

- uPowerTek provides 2 versions input voltages: 120-277Vac and 200-480Vac, and this full range covers most of the power grids in the world.

- The efficiency is extremely high up to 95.5%. The high efficiency results in the high light efficacy of the grow lights thus saves a lot of money for end customers.

- Extremely low inrush current. The standard version of 400-800W driver has only less than 20A so as to ease the selection of circuit breakers for existing systems.

- Great dimming performance. Dimmed down to 10% smoothly without any flickering.

- Full range and choices of output.

| Universal Input | Input Voltage | Output Power | Output Voltage | Minimum Current | Maximum Current | Certificate |

| TLD-800-C18A-XYZ-LV0000 | 108-305Vac | 800 W | 30-56Vdc | 14.5A | 18A | UL/FCC/CB/ENEC/CCC |

| TLD-700-C16A-XYZ-LV0000 | 108-305Vac | 700 W | 30-56Vdc | 12.5A | 16A | UL/FCC/CB/ENEC/CCC |

| TLD-600-C14A-XYZ-LV0000 | 108-305Vac | 600 W | 30-56Vdc | 11A | 14A | UL/FCC/CB/ENEC/CCC |

| BLD-400-C990-XYZ | 108-305Vac | 400 W | 24-58Vdc | 6.9A | 9.9A | UL/FCC/CB/ENEC/CCC |

| BLD-320-C700-XYZ | 108-305Vac | 320 W | 27-64Vdc | 5A | 7A | UL/FCC/CB/ENEC/CCC |

| BLD-240-C690-XYZ | 108-305Vac | 250 W | 22-52Vdc | 4.8A | 6.9A | UL/FCC/CB/ENEC/CCC |

| High Voltage Input | Input Voltage (Vac) | Output Power | Output Voltage | Minimum Current | Maximum Current | Certificate |

| TLD-800-C18A-XYZ | 180-528Vac | 800 W | 30-56Vdc | 14.5A | 18A | UL/FCC/CB/ENEC/CCC |

| TLD-700-C16A-XYZ | 180-528Vac | 700 W | 30-56Vdc | 12.5A | 16A | UL/FCC/CB/ENEC/CCC |

| TLD-600-C14A-XYZ | 180-528Vac | 600 W | 30-56Vdc | 11A | 14A | UL/FCC/CB/ENEC/CCC |

| TLD-400-C990-XYZ | 180-528Vac | 400 W | 24-58Vdc | 6.9A | 9.9A | UL/FCC/CB/ENEC/CCC |

| TLD-320-C700-XYZ | 180-528Vac | 320 W | 27-64Vdc | 5A | 7A | UL/FCC/CB/ENEC/CCC |

| TLD-240-C690-XYZ | 180-528Vac | 250 W | 22-52Vdc | 4.8A | 6.9A | UL/FCC/CB/ENEC/CCC |

- Ground cable at the output which makes the usage safer, and it is certified by UL Class P.

- High Reliability and long life time up to 100khours.

For more information, please contact with us by sales@uPowerTek.com.

Ref Docs:

- OSRAM Application Note: LEDs for horticultural lighting applications

- uPowerTek Application Note: uPowerTek Solution for Horticultural Application V1.3