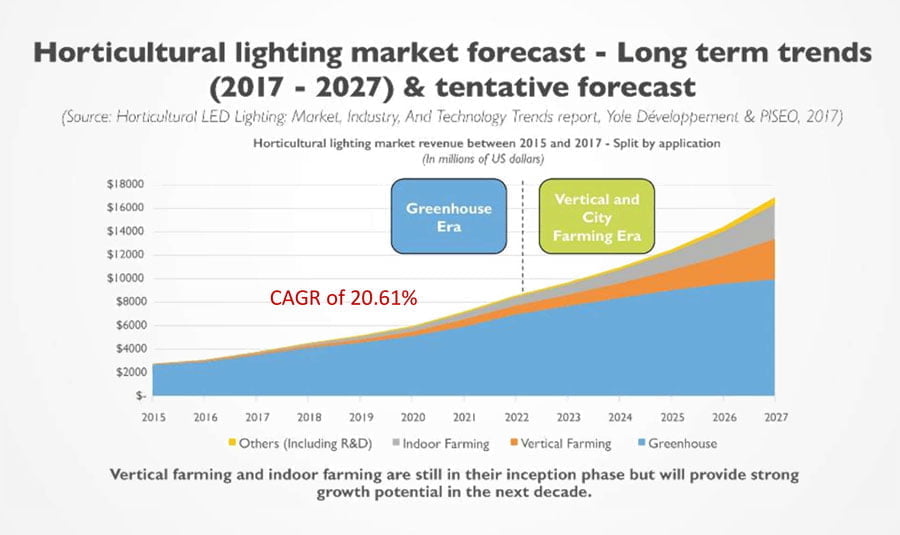

Grow light market experienced rapid growth in the year 2020-2021 and decline last year, and we believe that players in this industry will see a good recovery in the year 2023 since the major stock was consumed and the end customer demand is still growing. The players who are still alive after the recession realized that only quality and great products are the reasons that they can beat their competitors. And this article summarizes the main reasons that grow light may fail in the field.

Flickering

There are two kinds of flickering: visible and invisible.

Visible flickering is normally caused by the bad quality of LED driver and improper use of a good quality driver. One of the features of bad quality driver is about the consistency. Users can see some of the lights are good while some are flickering especially during dimming conditions. Grow lights are dimmed for more than 60% of the working period so the dimming performance is very important for growers. While the other factor that we have to pay attention to is that designers have to check about the operation range of the LED driver carefully including the input voltage range and LED load range. If in a project almost 90% of the lights flicker, maybe you have to check whether the light design is right within the normal operation range of LED drivers.

And stability of LED driver can also be affected to have some invisible flickering when the light system size is big, for example 200pcs of lights are tied to the same grid and the same control system. The common mode noises could spread through either the input cables or dimming cables. Thus big grow light system has much higher requirement on the stability of LED drivers. So LED driver design has to be fully verified and employ adequate EMI filters and margins for those kind of large system.

Dim-off Glow

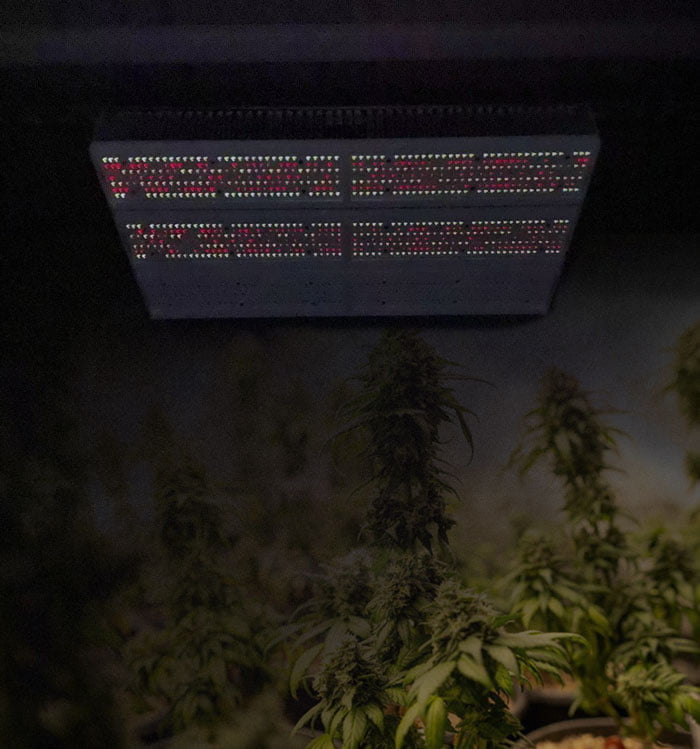

There are quite a few of plants like cannabis which are quite sensitive to light brightness when they fall asleep during the off-mode. If the luminaire designers don’t pay attention to the off-state glow, the cannabis yield rate can be greatly affected. There can be two main reasons for the dim-off glow.

- The LED driver does not totally shut down the output but just lower down the voltage to less than LED Von minimum value. This method can be good for over 80% LED chips but there are another 20% of LED chips which are quite easy to conduct even the voltage is very low. So the best way to shutdown LED is to make sure LED driver has 0V output in the off status, which means the LED driver is totally shutdown.

- The input voltage goes to LED chips through LED driver Y capacitors and LED board parasitic capacitors. There are quite a few grow light manufacturers recalled their products due to this issue in the past few years. Red LEDs are much easier to have this problem because of much less Von. To avoid this issue, LED driver manufacturers also have to provide properly designed Y capacitor combinations to help luminaire makers solve this issue.

Weak Surge Immunity

Grow lights are different from traditional high power ones which are normally installed outdoor. For outdoor luminaires, lightning is one of the biggest reasons that failure happens while for grow lights surge immunity is also important but not due to lightning since most grow lights are installed indoor. Then what happens? There are mainly two reasons that surge occurs in grow light application:

- Sudden on of generators. Most of the large grow systems have back-up electricity which are powered by generators which usually provides un-stable output compared with normally electricity from grid.

- On and off power from other rooms. Since grow light system consumes a lot of energy, the sudden on and off of a single system can create big surges on the power line.

The surges created due to both reasons are not the shape like lightning of high peak (~kV)and short period (us), but it can be several hundred volts with length of multiple milliseconds or even seconds. High quality LED drivers usually has good margins to endure the unstable sudden high voltage input.

Waterproof Issue

Most of high power LED drivers are IP67 or at least IP65 rated, and high IP rating is not only for waterproof but also for thermal management. However, there are still existing two reasons that the luminaires fail due to waterproof issue.

- Sprayed water. Quite a few growers use high -pressure water to wash the light fixtures. If the waterproof is not done well, there could be water inside the fixtures even into the LED drivers.

- Condensed water. Since the grow lights are dimmed up and down during the operation, the internal temperature can be also up and down, thus there could be condensed water inside a fixture or even LED drivers. The components which are not well waterproof designed may have possibility to fail after a period of time.

Improper Controller Design

90% of the grow light systems are controlled by smart centralized controller rather than manual operation. Improper system design can lead to several problems.

- Luminaires can not be well controlled or even blink. The users have to pay attention to the driving capability of the controller (~mA) and the sinking/sourcing current capability (~100uA) of the driver dimming interface. When the luminaires are paralleled too much to a single controller, the inadequate driving capacity of the controller may lead to un-predictive dimming failures.

- Inconsistency. For big grow light systems, the dimming cable can be long and hundreds of lights are paralleled in the system thus the voltage drop on the dimming cable should not be negligible especially the dimming level is low. 0.5V dimming voltage difference can lead to over 30% difference of the target dimming value.

- Incompatibility. The most common way to dim the lights is to use analog dimming like 0-10V which is output by the main controller, however, to achieve a better consistency, sometimes PWM dimming is utilized, and some application uses RS485 or some even more complicated protocols. The users have to be aware about what kind of dimming protocol the LED driver supports to make sure the system is well operated.

Summary

In general, grow light market is experiencing large fluctuation in the past years, as well as different kinds of light failures. To make sure of a high quality and stable grow light system, both luminaire designers and end users have to carefully utilize the LED drivers and understand the main reasons of the system failures. For more LED driver application notes, please contact with us to make the grow light system better.

Get in touch now!

Meet Our Team

We have a professional team to support you, you will get a reply within 24 hours, tell us more about your projects, let’s see what we can do for you.