LED technology not only provides improved efficiency and longer lifespan but also provides greater design freedom. If you want to take full advantage of the LED technology, class P LED drivers are here to help you!

Wondering what are class P LED drivers and why should you choose them? If yes, then you’re in the right place because this is what this article is all about.

Why Were Class P LED Drivers Created?

The Class P LED Driver program was created by UL (Underwriters Laboratories), a global safety science organization, to provide lamp manufacturers with more supply chain options for LED drivers. The UL’s mission is to create safe working and living environments for everyone. UL uses research and standards to continuously enhance and address ever-changing safety needs.

This organization has over 120 years of experience in developing innovative safety solutions. To maintain production safety standards and compliance, the company advises, audits, certifies, educates, inspects, tests, validates, and verifies products.

Another reason for using class P drivers is that it allows replacements between different LED drivers.

This program was created to assist manufacturers in conducting testing in accordance with product quality and safety guidelines while allowing for agility and innovation in a rapidly changing marketplace.

Hence, this program allows us to optimize and take full advantage of LED technology.

What Is Class P LED Drivers?

The Class P program was launched in January 2016 with the goal of better supporting luminaire makers by allowing freedom of substitution for LED drivers.

This program allows luminaire manufacturers to use different LED drivers without having to recertify their products. It’s a program that establishes guidelines for evaluating and testing standardized LED driver constructions and ratings.

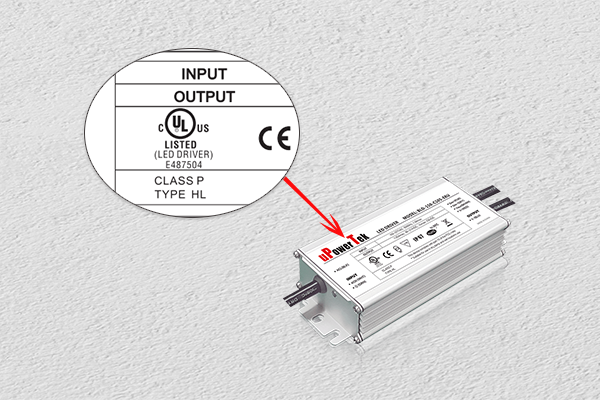

The Class P program is a UL-listed program. UL listing indicates that UL (Underwriters Laboratories) has tested a product, and it complies with nationally accepted safety standards and is free of a reasonably foreseeable risk of fire, electric shock, or other hazards.

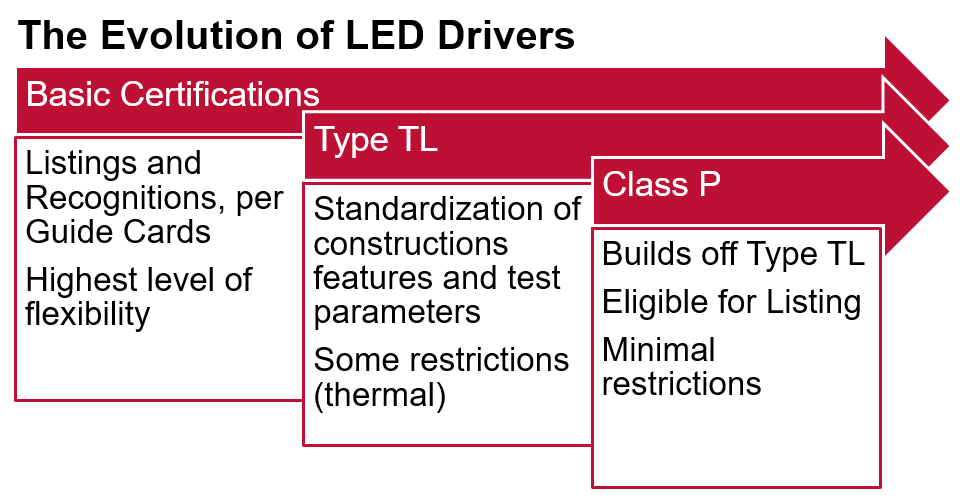

The Difference Between Class P And Type TL

LED Drivers with the TL program certification symbol on the driver label have an over-temperature protection mechanism and have passed UL’s standardizing temperature testing methods and fault testing requirements.

There are various differences between the Class P, and Type TL Led drivers, and one of them is: Class P LED driver is UL listed product, while Type TL is UL recognized product.

You might be thinking, what’s the difference between UL recognized, and UL listed. Let’s have a look:

UL Listed:

Underwriters Laboratories define UL Listed items as fully functional, stand-alone products or equipment that fit into a certain category or function. If a product is “UL Listed,” it has undergone extensive testing to meet UL industry and safety requirements, which might encompass everything from fire and flame resistance to mechanical operation and potential electrical risks.

Having your product listed by the Underwriters Laboratories (UL) indicates excellent quality and strengthens your brand’s reputation for safety and accountability.

UL Recognized:

“UL Recognized” is for components comprising a larger system, such as power supplies, electrical components, and even insulation materials. These components are meant to be included in bigger products or systems; therefore, they may be incomplete or have limited functionality.

In short, the UL Recognition service is mainly focused on machines and parts that are used to create other products.

To help you better understand the major differences between a class P and a type TL-led driver, we’ve listed their differences individually below.

Type TL LED Driver

- Type TL Led drivers are recognized LED Drivers, like parts and components

- Concentrate on the Tref value

- Consider temperature parameters while concentrating on the temperature of the LED driver and its internal components.

- Temperature parameters are used to ensure that internal parts and components do not exceed set temperatures, as well as the power supply’s dependability and life.

- The choice of replacement drivers by manufacturers depends on temperature.

Class P LED Driver

- Class P Led drivers are listed LED Drivers as finished items

- Do not consider temperature parameters.

- In the case of a failure, the power supply’s safety is more dependent on component safety.

- Set aside temperature parameters to allow for a more flexible replacement power supply option.

- Set aside temperature parameters in order to be more competitive in the market.

Requirements For The Class P LED Driver

Class P LED Driver is evaluated according to the applicable requirements of the Class P LED Driver in UL 8750. Following are the requirements Class P LED Drivers must have:

- Under normal rated load conditions, the maximum shell temperature of any point on the LED driver’s outside surface cannot exceed 90C.

- Under abnormal conditions, the maximum shell temperature of any point on the LED driver’s outer surface cannot exceed 110°C; however, it is allowed to reach 150°C in a short time. Abnormal conditions are component failure (short circuit or open circuit) conditions, in any under overload conditions, including output short circuits, and abnormal tests due to increased ambient temperature.

- The Class P LED Driver can also be evaluated by UL8750, the nominal Type IC LED Driver, which means that when the LED driver is installed in the lamp, it can directly contact the thermal insulation wool in the ceiling.

-

120-277Vac Input LED Driver1515 products

120-277Vac Input LED Driver1515 products -

180-528Vac Input LED Driver1111 products

180-528Vac Input LED Driver1111 products -

Constant Current LED Driver2929 products

Constant Current LED Driver2929 products -

Constant Voltage LED Driver1313 products

Constant Voltage LED Driver1313 products

Why Should Manufacturers Choose Class P LED Drivers?

Class P was created to give manufacturers a more flexible and time-saving way to avoid recertification and retesting. Manufacturers can cut costs, enhance their speed to market, and simply alter their product lines as a result of this.

The Class P program’s substitution and flexibility can help manufacturers with sourcing, avoiding long lead times, adapting current designs to match various application-specific requirements, and providing a simple way to improve your driver without having to pay additional fees for review.

This program is suitable for manufacturers that target a wide range of applications with a wide range of feature sets, employ the same fixture and load design for long periods of time.

Conclusion

The world of solid-state lighting is rapidly changing! Being able to accept new technologies quickly is more important than ever for a company’s success in the market.

Class P is a UL-provided thermal performance rating that can be added to show the cross-compatibility of different driver brands in the market for use in luminaires.

For standardized LED driver construction and ratings, the Class P program has established assessment and testing procedures. Luminaire makers now have more options when it comes to finding drivers that fulfill their design requirements while also having the necessary UL certification.

If you have any queries about the UL Class P program or UL Class P drivers, contact us here . We’ll be happy to assist you!