Choosing a power supply for your project can be challenging and tough because there are so many options and regulations to follow depending on where your project is located.

You may come across regulations that need a Class 2 or Class II power supply while working on your project, and it’s particularly challenging when deciding between Class 2 and Class II. These two classifications may sound similar, yet they mean very different.

Both are significant classifications, though, because they deal with the power supply’s and the user’s safety. Therefore, it’s important to understand different concepts about class 2 and class II LED drivers. The distinction between them is far greater than their names suggest!

So, what’s exactly the difference between class 2 and class II?

Let’s discuss both of them in detail!

UL Class 2 Definition

The UL Class 2 LED drivers comply with the UL1310 standard, which indicates that the output is considered safe to touch and does not require primary safety protection at the LED/luminaire level.

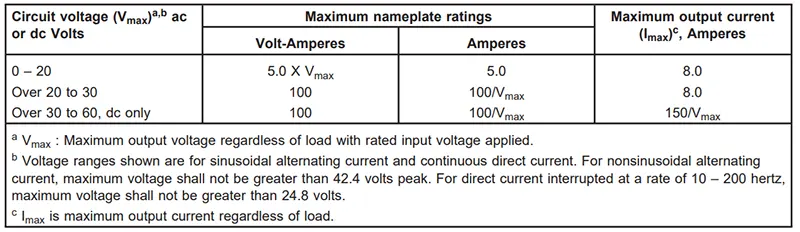

There is no danger of fire or electric shock. These LED drivers have a voltage rating of fewer than 60 volts (in dry applications) and 30 volts (in wet applications), a current rating of fewer than 5 amps, and a wattage rating of fewer than 100 watts. Due to these restrictions, the number of LEDs that a Class 2 LED driver can handle is limited.

To be classified as Class 2, a power supply must also meet the NEC’s requirements (The National Electric Code). The National Electric Code, often known as NFPA 70, is a set of rules and regulations that govern the safe design, installation, and inspection of electrical wiring and equipment in both residential and commercial locations.

These guidelines address the wiring requirements and power constraints of the power supply in order to reduce the risk of shock or fire. Here’s an overview of those requirements.

The power limitations of the power supply are the essential aspect of the NEC Class 2 standard. LED power supplies convert 120V electricity into low-voltage 12V or 24V electricity. 12V DC LED drivers must be 60W or less, and 24V DC LED drivers must be 96W or less in order for power supplies to be Class 2 compliant. These restrictions serve to reduce the risk of electric shock or overheat caused by high currents.

High-wattage multi-tap driver has 5 separate 60W outputs, each with its own circuit breaker, ensuring that if one of the outputs experiences a surge, the others are unaffected. It’s like having numerous LED drivers and a junction box in one unit, and it’s a more cost-effective and simple-to-install alternative to employing multiple 60W LED drivers. Only one switch controls all outputs, so you won’t need multiple switches unless you need individual control for a section of lighting, such as a dimmer.

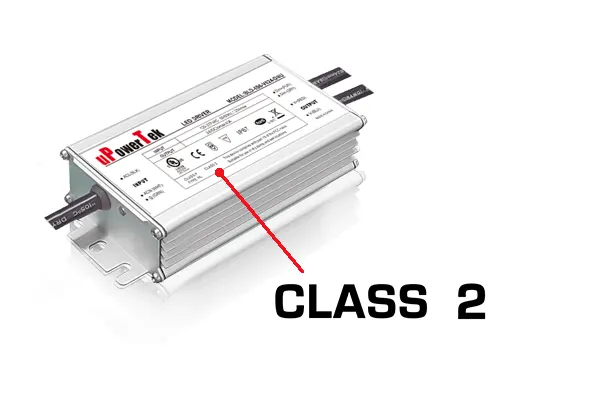

Power supplies that meet the Class 2 standard are always labeled or marked as so.

Class 2 power supply must be built with In-Wall Rated wire for permanent installation inside walls or floors, where insulation may be present. The NEC approves Class 2 In-Wall Rated Wire for installation inside walls because it adds an extra layer of protection against cracking and melting.

Check uPowerTek class 2 LED drivers here.

Class II LED Driver

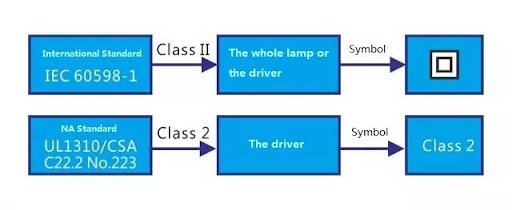

To be classified as Class II, which differs from Class 2, a power supply must comply with the IEC’s design guidelines (International Electrotechnical Commission) which relates to the internal construction and electrical insulation of the power supply.

A Class II power supply has two layers of insulation (or a single layer of reinforced insulation) between the user and the internal current-carrying conductors. And the first layer is commonly referred to as “Basic Insulation.” The insulation seen surrounding the wires coming out of the power supply is known as basic insulation. The second layer of insulation is typically an insulating casing that encloses the product, such as the plastic case found on wall mounts and desktop power supplies.

Class II power supplies are identifiable on the label by a large square with a smaller square inside it.

To protect against shock hazards, Class II supplies do not rely on an earth connection. Many external power supplies are likewise classified as Class II since they only have a Line and Neutral AC input and no ground connection.

Instead of a three-wire power cord with a ground wire for protection, the Class II power supply will feature a two-wire power cord.

Difference between Class 2 and Class II

| Classify | Class 2 | Class II |

|---|---|---|

| Standard Institution | UL/CUL/NEC | IEC |

| Description | Output (<100W, <60V,<5A) | Input (Two-wire power cord) |

| Insulation | Electrical limitation | Double Insulated |

| Related Concepts | Class 1 | Class I |

IEC Class I and Class II

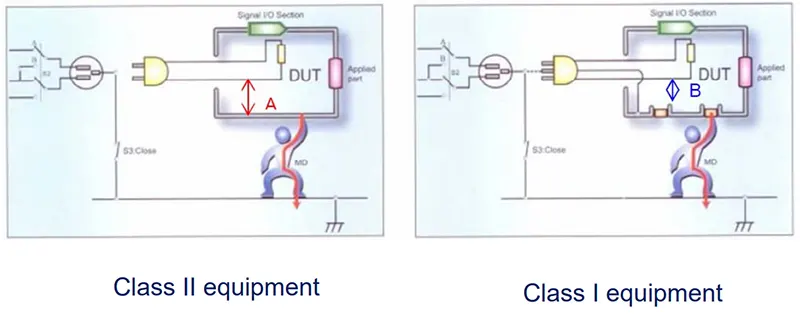

IEC Class I input models have basic insulation and must include a safe earth (ground) connection to reduce the risk of electric shock.

IEC Class II input types include extra safety precautions, including double insulation or reinforced insulation, which eliminates the necessity for a protective earth (ground) connection.

The insulation clearance of class II has to be much larger than class I devices as figure below shows.

Summary

The Class 2 and Class II classifications refer to the safety features in place to avoid electrical shock and fire initiation rather than the capabilities of the power supply themselves.

Understanding the differences between two power supply options can help in picking the correct product for the job.

In general, Class 2 labels refer to a power supply’s output capability, whereas Class II designations refer to interior construction and insulation of a power supply.

If you are looking for class 2 LED drivers, you can check uPowerTek UL class 2 LED drivers here.

Class 2 LED Drivers