People in the LED industry often complained that the LED lamp is damaged easily, because the LED driver is broken. So the most unreliable part in the LED lamp is the LED driver. Maybe he is telling the truth. But we also need to analyze the reason why the LED driver is damaged.

Recently, the LED lamps in my house was also broke down. When I took apart it, it turned out that the LED driver was broken, I decided to analyze it carefully.

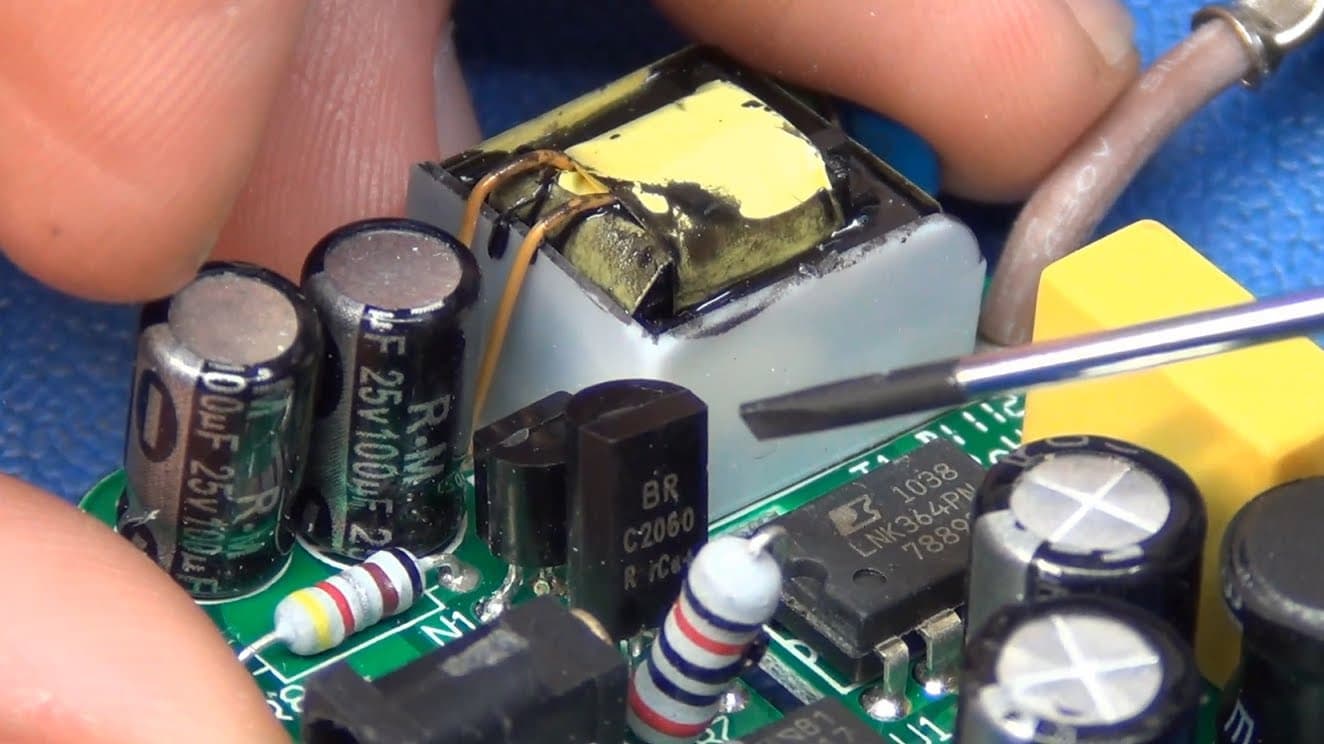

First take a look at the product:

Although it is a very simple product, we can see many problems. These are common problems of all unreliable LED drivers.

1. Using cheap and low-quality components

We can see that its rectifier bridge (left in the picture) is composed of 4 rectifier diodes instead of using an integrated rectifier bridge.

We know that the cost of four diodes is much lower than that of an integrated rectifier bridge, because there are many companies can produce diodes. Using some of the simplest semiconductor production equipment that has been eliminated in the past can produce diodes. However, there are not so many companies that could produce integrate rectifier bridges. Because they must have high-quality integrated circuit production equipment and raw materials, which are produced by some large manufacturers, and their prices are definitely much higher than four diodes’.

In fact, high reverse voltage diodes are hard to produce, and small manufacturers may not be able to produce very reliable high reverse voltage diodes. Later, I measured with a multimeter, it turned out that a rectifier diode was broken, but the electrolytic capacitor was still fine.

So is there no problem with the integrated rectifier bridge?

Not really, electrolytic capacitors are broken down because they are not protected in many cases.

In addition, the withstand voltage and power consumption of the components should be considered, try to leave margin as much as possible, such as the withstand voltage of the electrolytic capacitor. Although the peak voltage is only 220Vx1.4 = 308V at the rated 220V. The withstand voltage of the electrolytic capacitor on the power board is 400V, which should be enough. However, we usually choose 450V electrolytic capacitors, so the insurance factor can be higher.

2.No protection components

It can be seen from the photos, this LED driver is not equipped with any protective devices.

However, protection components must be added to an AC input driver. Because there would be various surge voltages, which may be a lightning strike at a long distance or high voltage pulses caused by switching a high-power device on the grid.

The electrolytic capacitor would easily be damaged if there is no high-voltage pulse protection.

◆ ◆ ◆ ◆

Devices to Protect the LED driver

There are two functions of the LED driver protection circuit, one is to protect the LED driver from being damaged by external factors. On the other hand, it protects the external circuit environment and prevents external circuits from being affected by the operation or failure of the LED lamps.

The most important protection devices as below:

Varistor

It is used to protect the LED luminaire. No matter what kind of LED driver the LED luminaire uses, like switching power supply or linear LED driver, they require the protection. It is used to prevent the surge voltage that often occurs on the AC network.

Surge voltage is mainly due to short-term high-voltage pulses caused by lightning strikes or high-power electrical equipment starting and stopping. Lightning strikes are the main reason.

Lightning strikes can be divided into two types: direct lightning strikes and indirect lightning strikes. Direct lightning strikes refer to the fact that lightning strikes the LED driver network directly. This possibility is rare, and most large power grid systems have lightning protection functions.

Indirect lightning strikes are surges transmitted on the power grid induced by lightning. Such surges are very likely to occur, because there are 1800 thunderstorms and 600 lightnings per second worldwide. Each lightning strike induces a surge voltage on the nearby grid.

The width of a surge pulse is usually only a few microseconds or even shorter, and the amplitude of the pulse can be as high as several thousand volts. Mainly because of its high amplitude, it has the greatest impact on damage to electronic equipment.

If without protection, all kinds of electronic equipment could be easily damaged. Fortunately, the protection against surges is very simple, as long as an anti-surge varistor is added, which usually is connected in parallel before the rectifier.

The principle of this varistor is very simple, there is a non-linear resistor whose resistance value is close to an open circuit within a specified threshold range, and once the applied voltage exceeds the threshold value, its resistance value approaches zero immediately. This makes it easy to absorb this surge.

Moreover, the varistor is a recoverable device. After the surge is absorbed, it can then play a protective role.

Here are the main specs of the varistor:

1. Maximum continuous working voltage (divided into AC and DC, such as DC 415V),

2. Varistor voltage (threshold value, such as 510V) refers to the starting voltage when the current is greater than 0.1mA.

3. The maximum limiting voltage refers to the maximum peak voltage Vp, such as 845V, under the peak current Ip (eg 200A) that the varistor can withstand. In fact, the surge is usually only a small width (several microseconds) Narrow pulse, the relationship between its voltage and current can no longer be described by resistance, because it is actually a non-linear device.

Negative temperature coefficient resistance NTC

Many LED drivers have electrolytic capacitors behind the rectifier. The charging current of electrolytic capacitors when they are powered on is usually very large and often measured in a few amps.

If there are many such power sources connected in a room at the same time, the combined charging current will cause the room’s power grid to generate a large instantaneous current, which is sufficient to trip the fuse.

Therefore, in order to avoid such kind of situation, a negative temperature coefficient resistor (NTC) must be installed in front of the electrolytic capacitor in the LED driver. Its characteristic is that the resistance is usually small. When it encounters an instantaneous large current, its resistance becomes extremely large instantly due to heat generation, which limits the instantaneous high current. When the large current passes, it will quickly return to the usual small resistance, thus avoid external impact from the LED driver.

Fuse

Its function is similar to ordinary fuses. When the LED load is short-circuited for various reasons, the fuse on it will immediately disconnect the short-circuited load to avoid tripping the external circuit.

The positions of the above three protection devices in the circuit of the LED driver are shown below:

The varistor is actually a varistor to prevent surges. These three protection devices are the most basic components and are a standard protection circuit which should be used in all LED drivers.

Unfortunately, most LED drivers in the market do not have this protective circuit. Only a few high-end LED driver use it.

For example, many non-electrolytic capacitor light engines or AC LED light engines that are claimed no driver requirement do not use this protection circuit. Because the height of the previous varistor is very high, which is around 4-5mm, so it can be immediately seen whether the anti-surge varistor is installed.

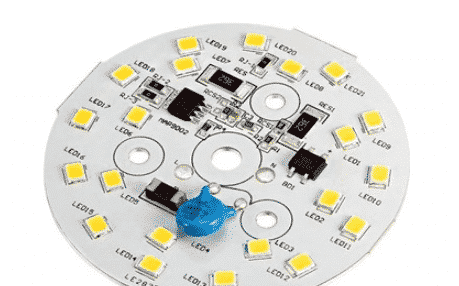

Here is an example of these “driver-less” and “AC LED” light engines:

These products can clearly be seen without any protective components.

Surge protection of LED street lights

There are two types of street lights, one is solar street light, the other is AC street light.

Because solar street lights do not need to be connected to the power grid, there is no surge problem; however, they are likely to be directly hit by lightning because they are often installed in open places. Therefore, most solar street lights need to be equipped with lightning rods to directly let the lightning strikes into ground.

In addition to installing lightning rods for AC street lights, surge protection is the most important issue. The power system may be installed in the wild and distributed in a long distance, the possibility of direct lightning strikes is also increased. At this time, the surge becomes wide pulses that are very destructive, it requires more effective anti-surge measures. In this case, a small varistor is not enough, and it must be changed to a gas discharge tube. This is a gas discharge tube with a gas discharge gap formed by a metal electrode and a porcelain tube sealed. A ceramic insulator and electrode are used. The welded housing ensures the air-tightness of the discharge gap.

When a high-voltage pulse acts on it, the gas is punctured, which cutting off the pulse high-voltage and protecting the subsequent circuit.

Conclusion

Above all, it is not difficult to make a high reliable LED driver, as long as the following points are followed:

1. Use high quality components. In fact, people who have common sense know that they get what they pay. The difference lies in reliability. So don’t sacrifice reliability for the sake of low price, it will finally ruin your company’s reputation.

2. When choosing the component parameters, leave some space such as the withstand voltage. You cannot assume that the mains voltage is 220V. Generally, we are required to at least consider that the voltage may be as high as 265V or even higher. So there must be space left for any engineering design.

3. The circuit design must use protection devices. A circuit without a protection device is like the door in your house without a lock. Do you dare to live in a house without a lock?

4. Better circuit boards should also be coated with three-proof paint: moisture-proof, salt-spray-proof, mildew-proof, plus dust-proof, leakage-proof, and better waterproof (IP67). In this way, the long life warranty of the circuit board can be ensured.

5. Some exported circuit boards also require CE, UL certification, and some also require ROHS certification (that is, lead-free certification), so as to avoid lead poisoning when recycling these circuit boards.

If you do the above, the life of the LED driver can be as high as tens of thousands of hours. In the past, many home appliances, such as televisions, have been used for more than ten years, which means that high reliability can be achieved.

Unfortunately, more than 80% of LED drivers on the market today are designed to reduce costs without using any protection devices. This method of harming others to benefit oneself should really be condemned by the public!

On the other hand, LED lamps that use this LED drivers are usually cheap. We have to advise consumers that they get what they pay.

uPowerTek LED driver has the most powerful protection functions, such as OTP, OCT and short circuit protection, the surge protection level is 10kV, and the LED driver could survive at least for 2 hours at 380Vac input, please contact our sales for more product info.